010203

Troubleshooting Techniques for PCBA: Common Methods for Identifying and Resolving Faults

2024-03-21 20:17:27

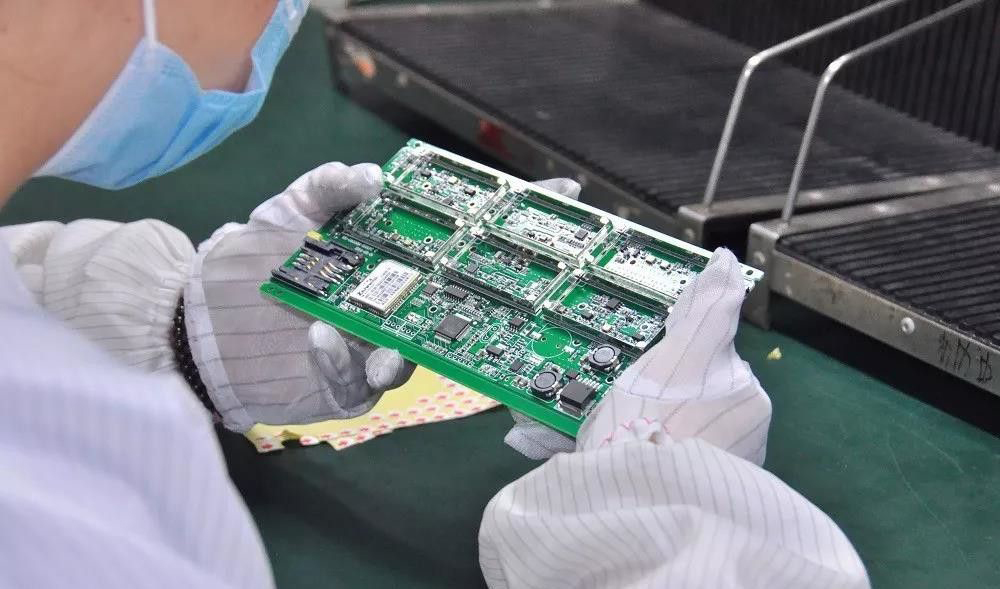

In the realm of electronics manufacturing, Printed Circuit Board Assembly (PCBA) troubleshooting is an essential skillset for ensuring product quality and reliability. This blog aims to share common techniques and methods for identifying and resolving PCBA faults, including the use of testing equipment, data analysis, and practical strategies.

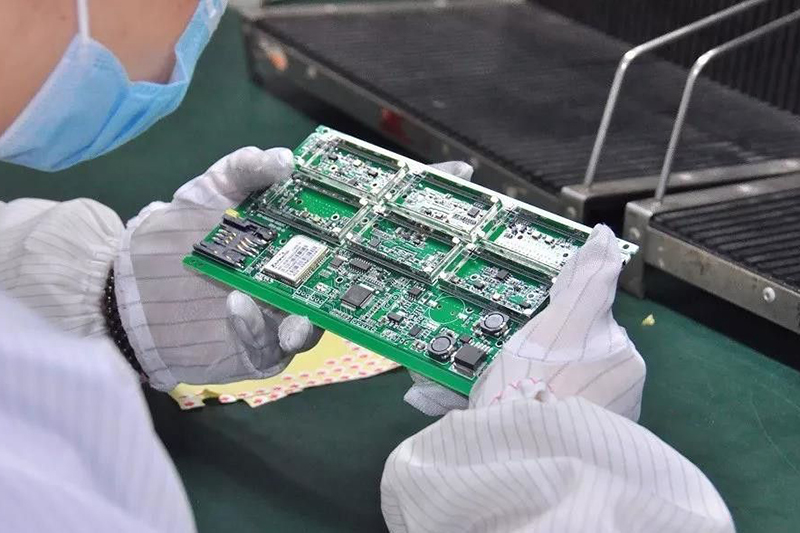

1.Visual Inspection:

Visual inspection serves as the initial step in PCBA troubleshooting, allowing technicians to identify obvious defects such as:

Solder Joint Issues: Check for solder bridges, cold solder joints, and insufficient soldering.

Component Damage: Look for physical damage, misaligned components, or missing parts.

Burn Marks and Corrosion: Inspect for burn marks, discoloration, or corrosion on components or PCB traces.

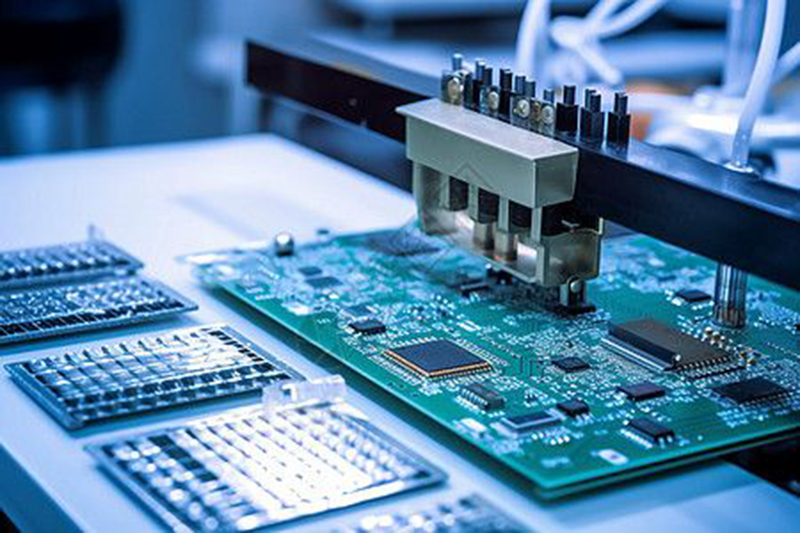

2.Functional Testing:

Functional testing verifies the performance and functionality of the PCBA under normal operating conditions. Techniques include:

Power-On Test: Apply power to the PCBA and observe its behavior, checking for proper power-up sequence, LED indicators, and functional responses.

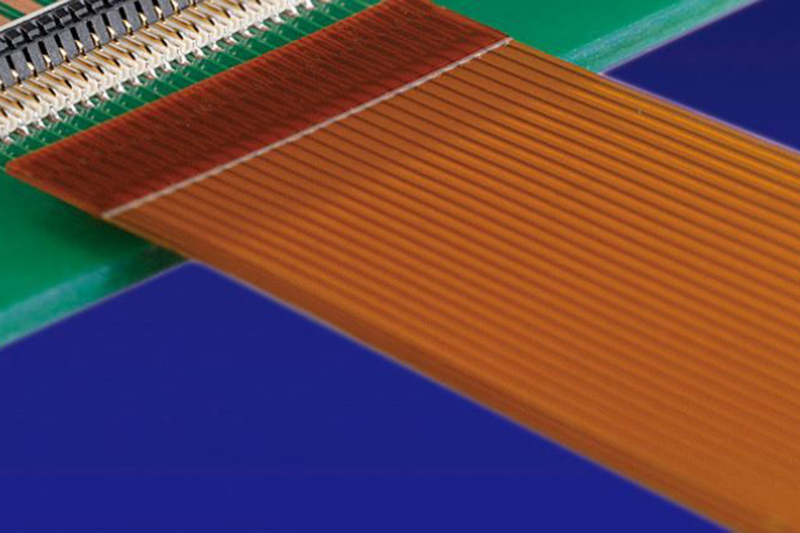

Input/Output Testing: Test input/output ports and interfaces for proper operation, ensuring connectivity and signal integrity.

Boundary Scan Testing: Utilize boundary scan techniques to test digital ICs and verify interconnectivity, particularly useful for complex PCBAs with multiple components.

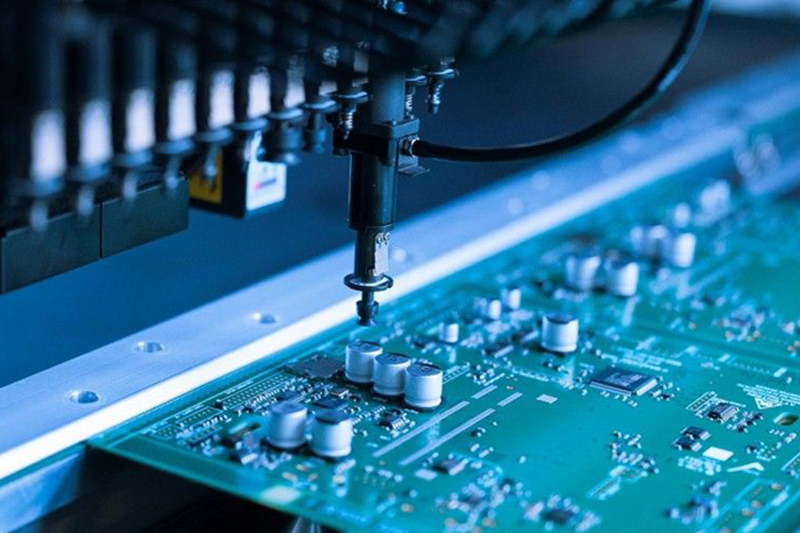

3.In-Circuit Testing (ICT):

ICT involves testing individual components and circuits while the PCBA is powered on. Key techniques include:

Continuity Testing: Verify electrical continuity across traces, vias, and component terminals using a multimeter or continuity tester.

Component Testing: Test resistors, capacitors, diodes, and other discrete components for proper values and functionality.

IC Functional Testing: Test integrated circuits (ICs) for proper functionality, clock signals, and communication protocols using specialized IC testers or protocol analyzers.

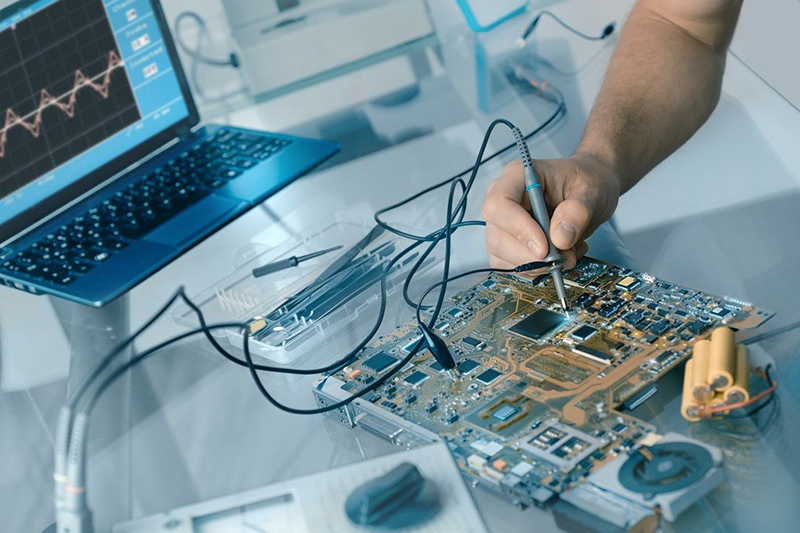

4.Advanced Testing Equipment:

Employ advanced testing equipment to diagnose complex faults and analyze PCBA performance:

Oscilloscopes: Use oscilloscopes to analyze analog and digital signals, detect noise, and troubleshoot signal integrity issues.

Logic Analyzers: Capture and analyze digital signals and communication protocols, facilitating debugging of digital circuits and interfaces.

Thermal Imaging Cameras: Detect hot spots, thermal anomalies, and overheating components indicative of potential faults or failures.

5.Data Analysis and Troubleshooting Software:

Leverage data analysis tools and troubleshooting software to analyze test results, identify patterns, and diagnose elusive faults:

PCBA Design Files: Refer to PCB layout files, schematics, and Bill of Materials (BOM) to cross-reference component placement, connections, and specifications.

Fault Log Analysis: Review error logs, test reports, and historical data to identify recurring faults, trends, or environmental factors contributing to failures.

Simulation and Modeling: Utilize simulation software to simulate PCBA operation, validate design assumptions, and identify potential failure modes before production.

In conclusion, mastering PCBA troubleshooting techniques is essential for ensuring product quality, reliability, and customer satisfaction. By employing a systematic approach, leveraging testing equipment, and analyzing data effectively, technicians can diagnose faults accurately and implement timely solutions, minimizing downtime and optimizing PCBA performance.