01020304

Automation and Intelligence in PCBA Manufacturing: Advantages, Challenges, and Innovations

2024-03-21 20:21:38

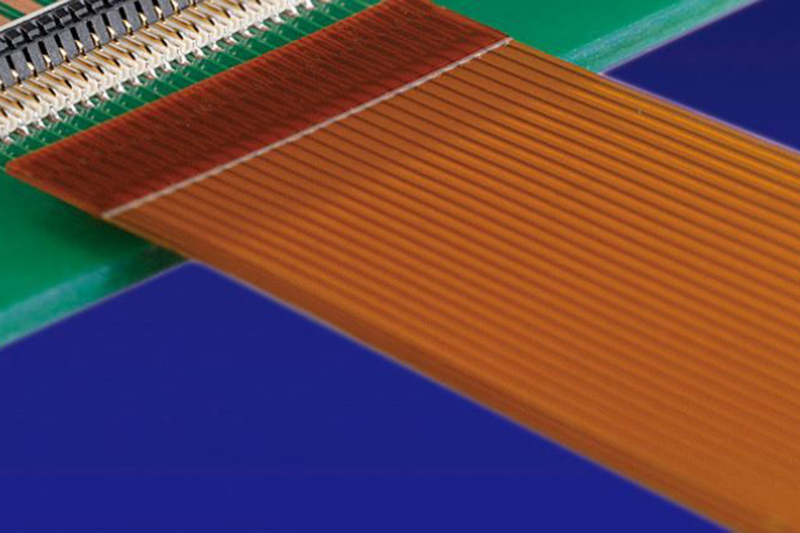

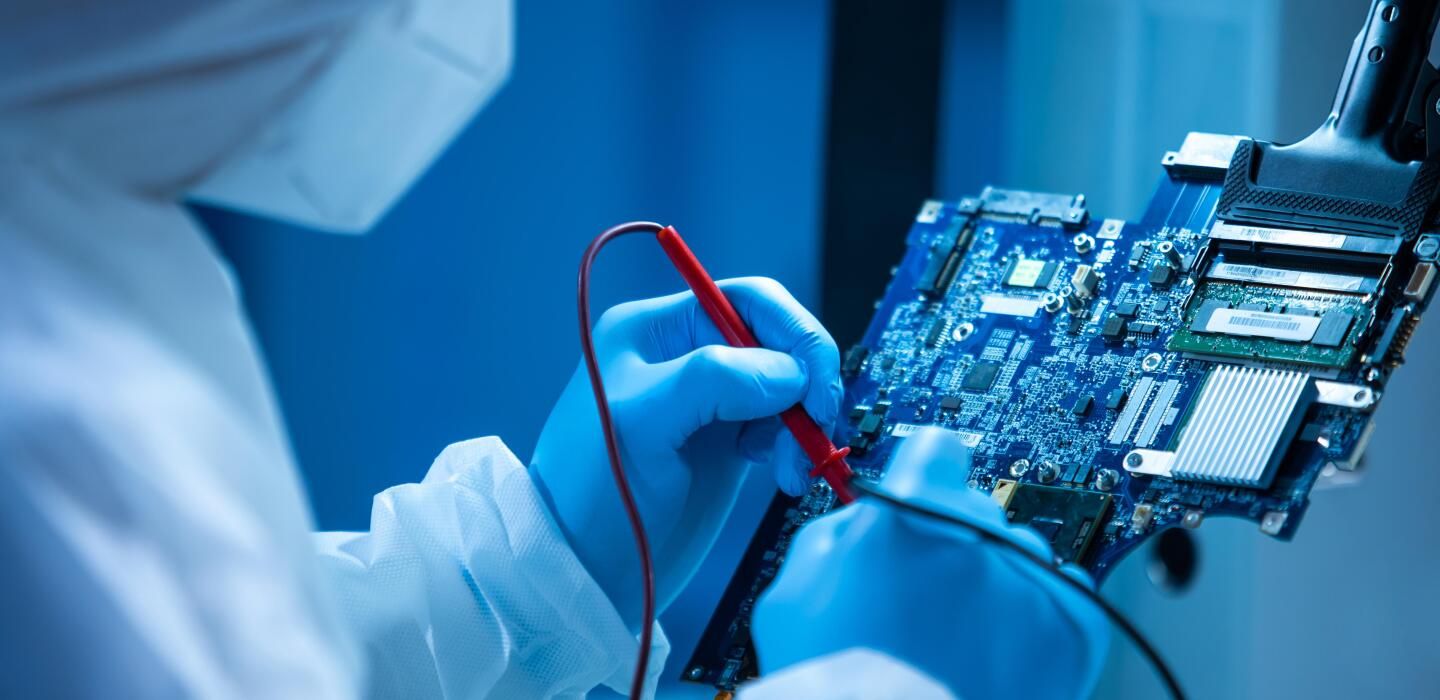

In the realm of electronics manufacturing, the integration of automation and intelligence technologies revolutionizes the Printed Circuit Board Assembly (PCBA) process, offering numerous benefits while presenting unique challenges. This blog explores the advantages, challenges, and innovative applications of automation and intelligence in PCBA manufacturing, including robot assembly, AI-powered quality control, and more.

1.Advantages of Automation and Intelligence:

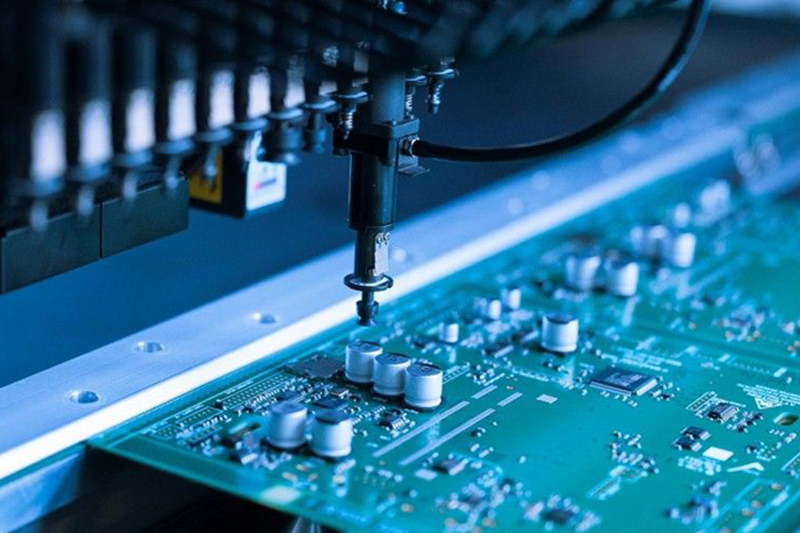

Increased Efficiency: Automation streamlines repetitive tasks, such as component placement and soldering, reducing cycle times and increasing throughput.

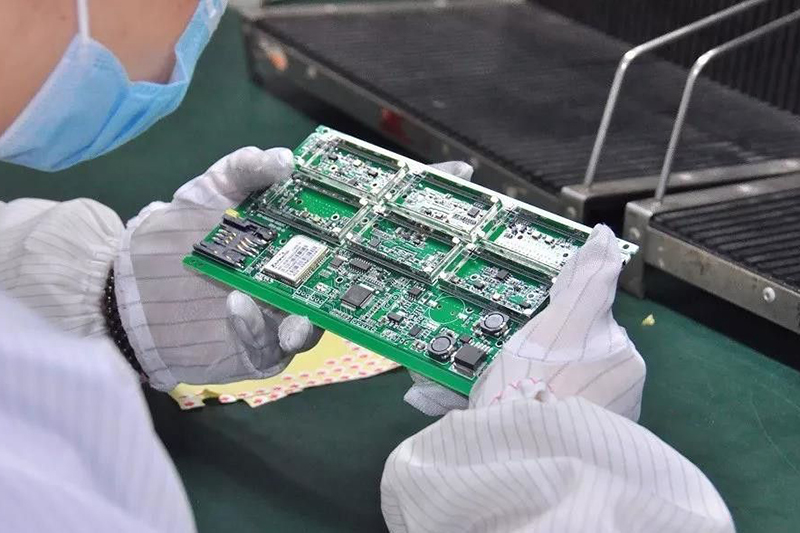

Enhanced Precision: Robots and automated systems offer precise component placement and soldering, minimizing errors and improving product quality.

Cost Reduction: Automation reduces labor costs associated with manual assembly, leading to overall cost savings in PCBA manufacturing.

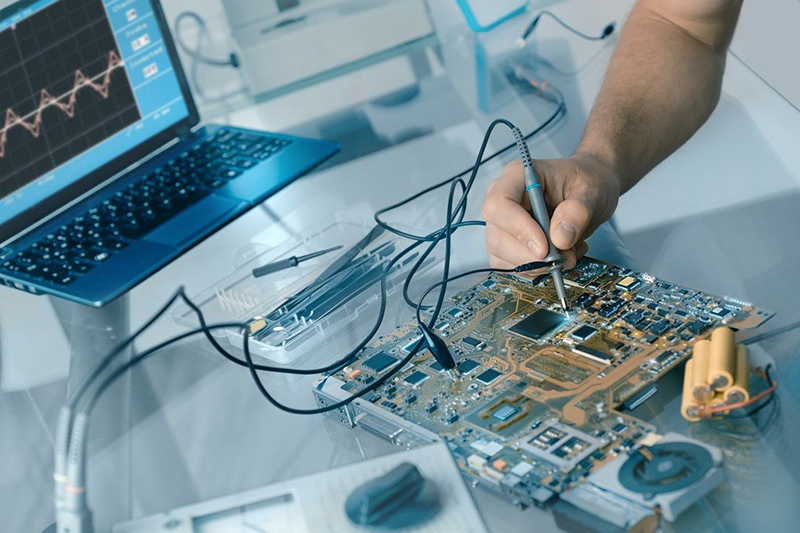

Improved Quality Control: Intelligence technologies, such as AI-powered inspection systems, enhance quality control by detecting defects with high accuracy and reliability.

Scalability: Automated processes can be easily scaled up or down to meet production demands, ensuring flexibility and adaptability in manufacturing operations.

2.Challenges in Implementation:

Initial Investment: The upfront cost of implementing automation and intelligence technologies can be significant, requiring careful financial planning and ROI analysis.

Integration Complexity: Integrating automation systems with existing manufacturing processes and infrastructure may pose technical challenges, requiring expertise and resources.

Skill Gap: Operating and maintaining automated equipment may require specialized skills and training for personnel, necessitating workforce development initiatives.

Interoperability Issues: Ensuring compatibility and interoperability between different automation systems and software platforms can be challenging, requiring seamless integration and communication protocols.

Security Concerns: With increased connectivity and data exchange in intelligent manufacturing systems, cybersecurity risks and data privacy concerns become prominent, requiring robust security measures.

3.Innovative Applications:

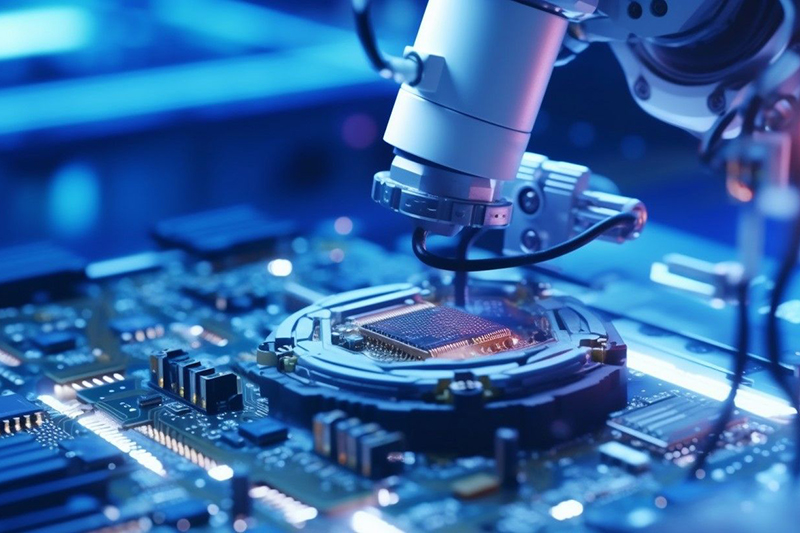

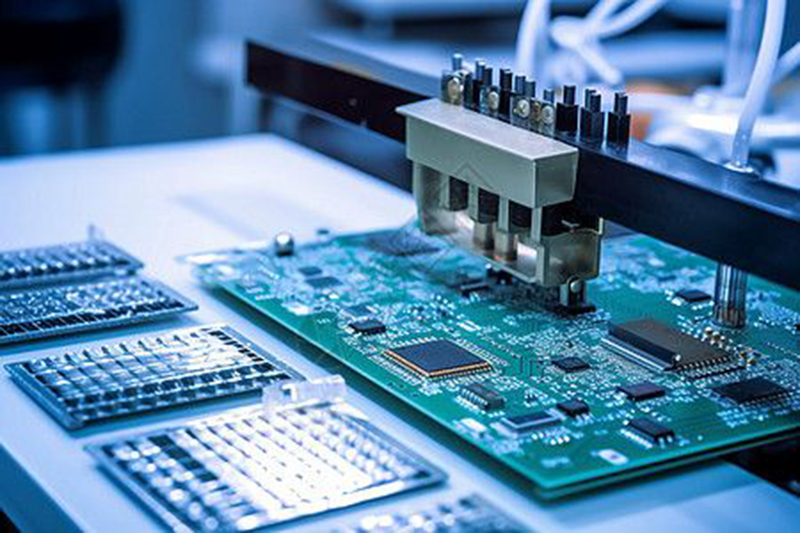

Robotics in Assembly: Automated pick-and-place robots and soldering machines streamline component placement and soldering processes, improving efficiency and precision.

AI-Powered Inspection: Artificial intelligence algorithms analyze images from cameras and sensors to detect defects such as soldering defects, component misalignment, and solder bridges with high accuracy.

Predictive Maintenance: IoT-enabled sensors monitor equipment health and performance parameters, predicting maintenance needs and reducing unplanned downtime.

Smart Manufacturing Platforms: Integrated manufacturing platforms leverage data analytics and machine learning to optimize production processes, improve yield, and enable real-time decision-making.

In conclusion, automation and intelligence technologies offer compelling opportunities for enhancing efficiency, quality, and scalability in PCBA manufacturing. While challenges exist, innovative solutions and strategic investments can help manufacturers harness the full potential of automation and intelligence, driving advancements and competitiveness in the electronics industry.