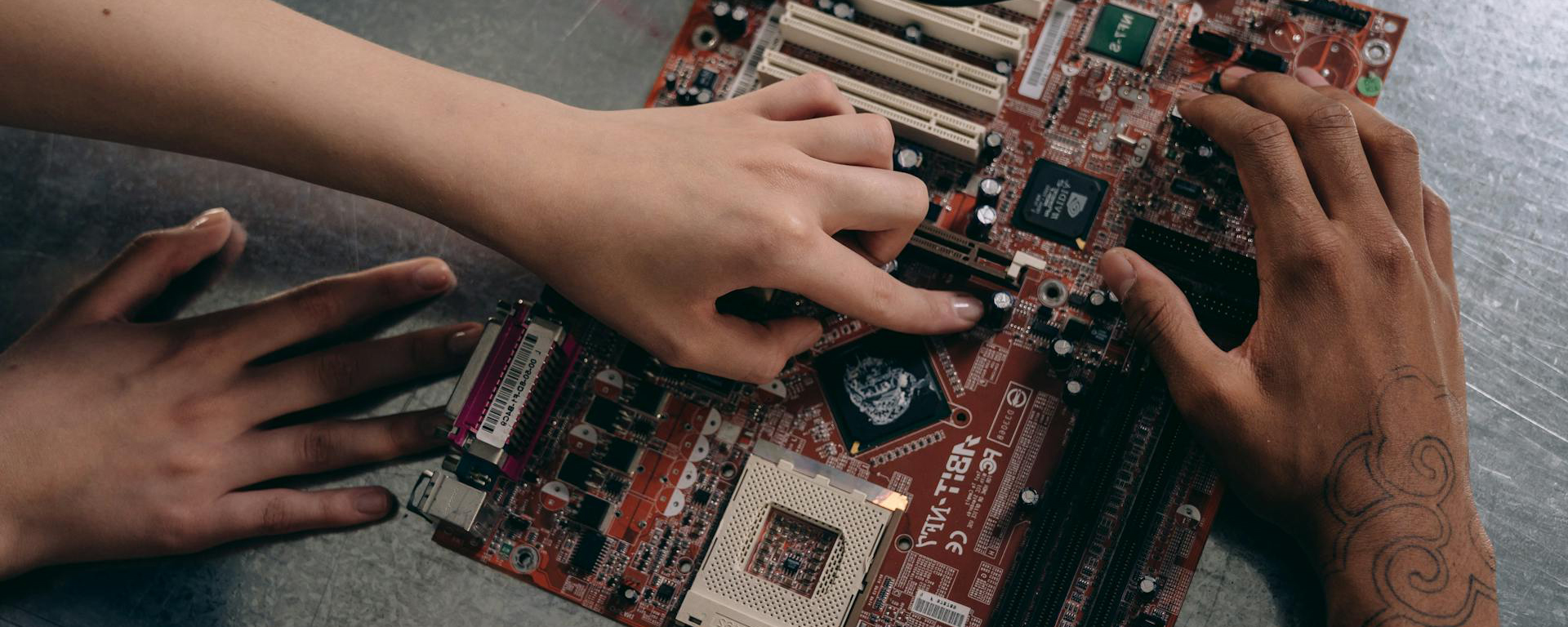

PCBA, short for Printed Circuit Board Assembly, refers to the process of assembling electronic components (such as resistors, capacitors, integrated circuits, etc.) onto a printed circuit board (PCB), followed by soldering, testing, and final assembly to create a complete electronic product.

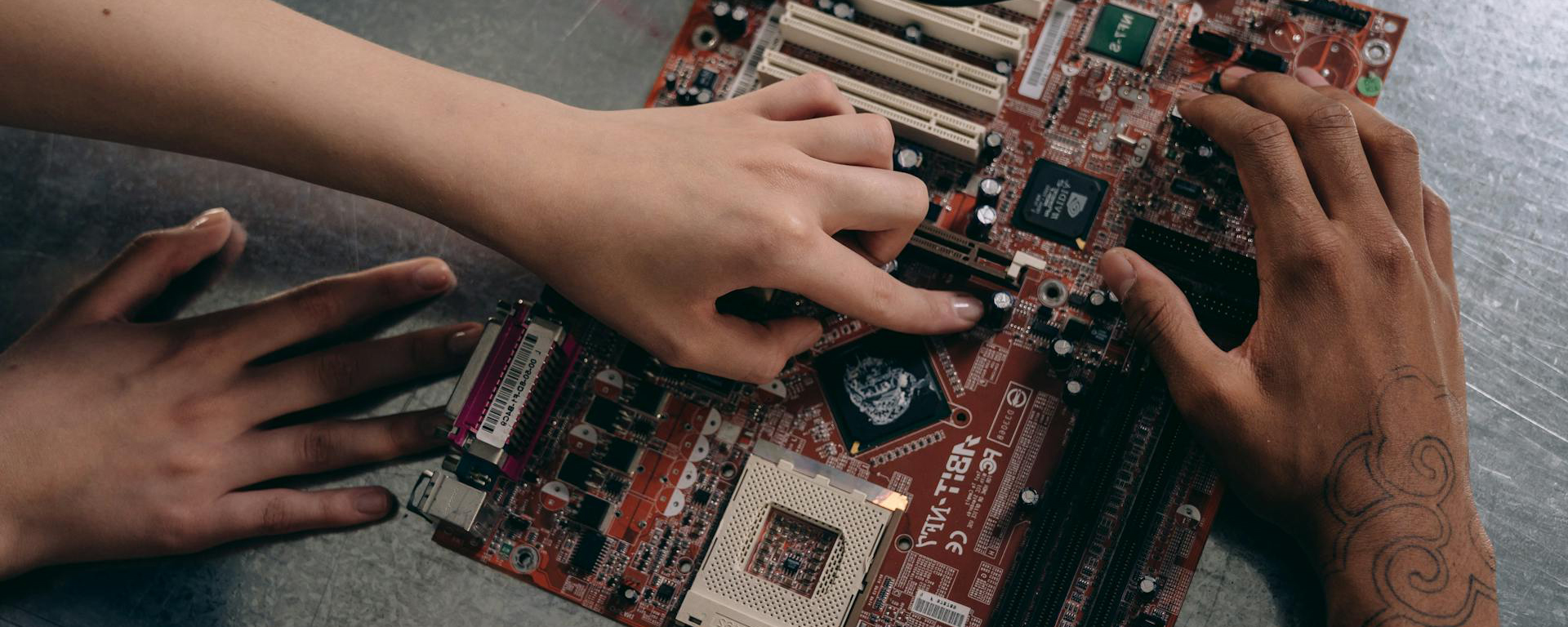

During the PCBA process, electronic components are mounted onto the PCB using various techniques such as surface mount technology (SMT) or through-hole technology (THT), depending on the design requirements and component types. Once the components are mounted, they are soldered onto the PCB to establish electrical connections.

After soldering, the assembled PCB undergoes testing to ensure that all components are properly installed and functioning according to specifications. This testing may include functional testing, in-circuit testing, and other quality control measures to verify the integrity and reliability of the assembled PCB.

Once testing is complete and any necessary adjustments are made, the assembled PCB is then integrated into the final product assembly, which may include additional components, enclosures, wiring, and other necessary elements to create a finished electronic device.

PCBA is a critical stage in the manufacturing process of electronic products, ensuring that they meet quality standards, functionality requirements, and performance expectations. It involves a combination of technical expertise, precision assembly techniques, and rigorous quality control measures to produce reliable and high-quality electronic products.