01

Environmental Sustainability in PCBA Manufacturing and Disposal: A 2024 Perspective

2024-03-21 20:07:51

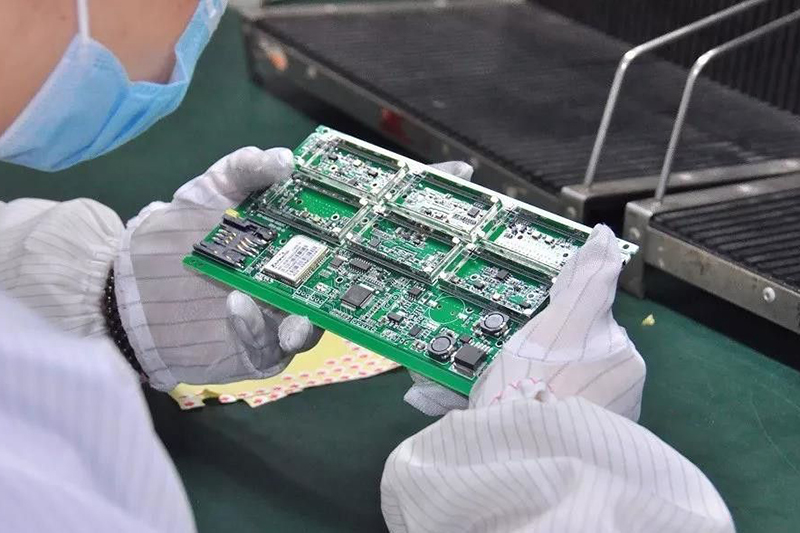

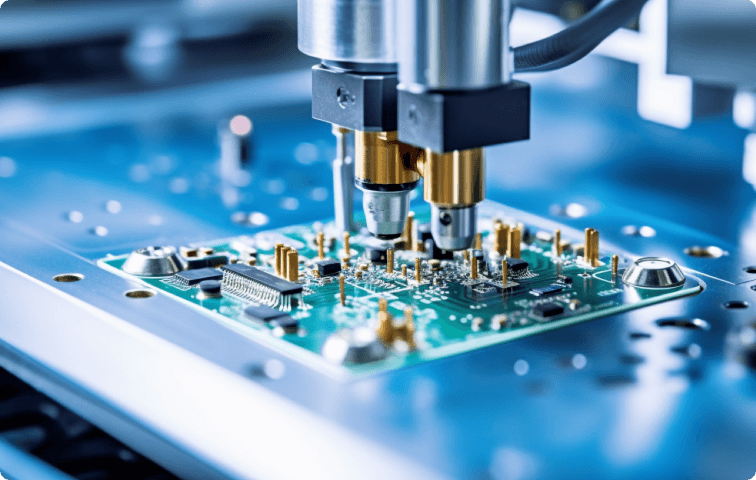

In the realm of electronics manufacturing, Printed Circuit Board Assembly (PCBA) plays a pivotal role in powering our interconnected world. However, as technological advancements surge forward, so too do the environmental challenges associated with PCBA production and disposal. In this blog post, we delve into the pressing environmental issues surrounding PCBA manufacturing and explore sustainable development measures across material selection, electronic waste management, and energy consumption.

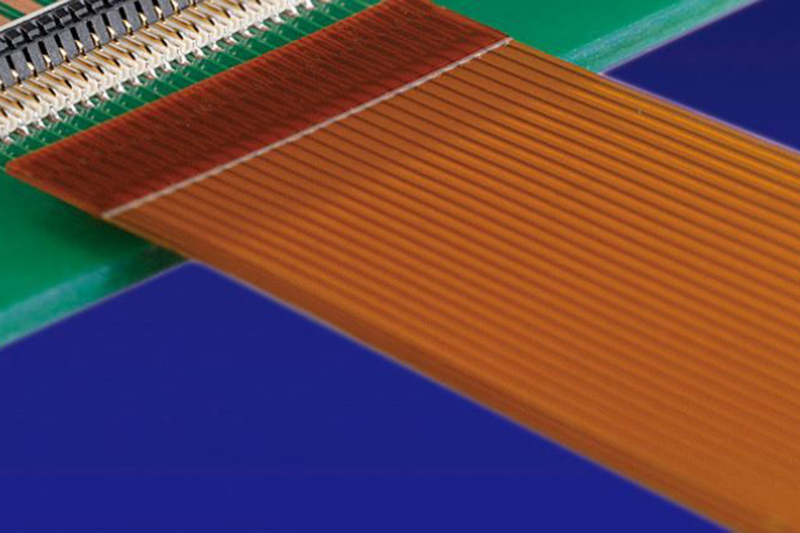

1.Material Selection for Sustainability:

The environmental impact of PCBA manufacturing begins with material selection. In 2024, the industry continues to prioritize sustainability through:

RoHS Compliance: Embracing RoHS-compliant materials to reduce the use of hazardous substances, thus mitigating environmental pollution and health risks.

Recyclable Materials: Opting for recyclable materials in PCB substrates, solder masks, and component packaging promotes circular economy principles, facilitating material recovery and reuse.

Low-Impact Alternatives: Exploring eco-friendly alternatives like bio-based plastics and renewable substrates to minimize the ecological footprint of PCBA manufacturing while preserving natural resources.

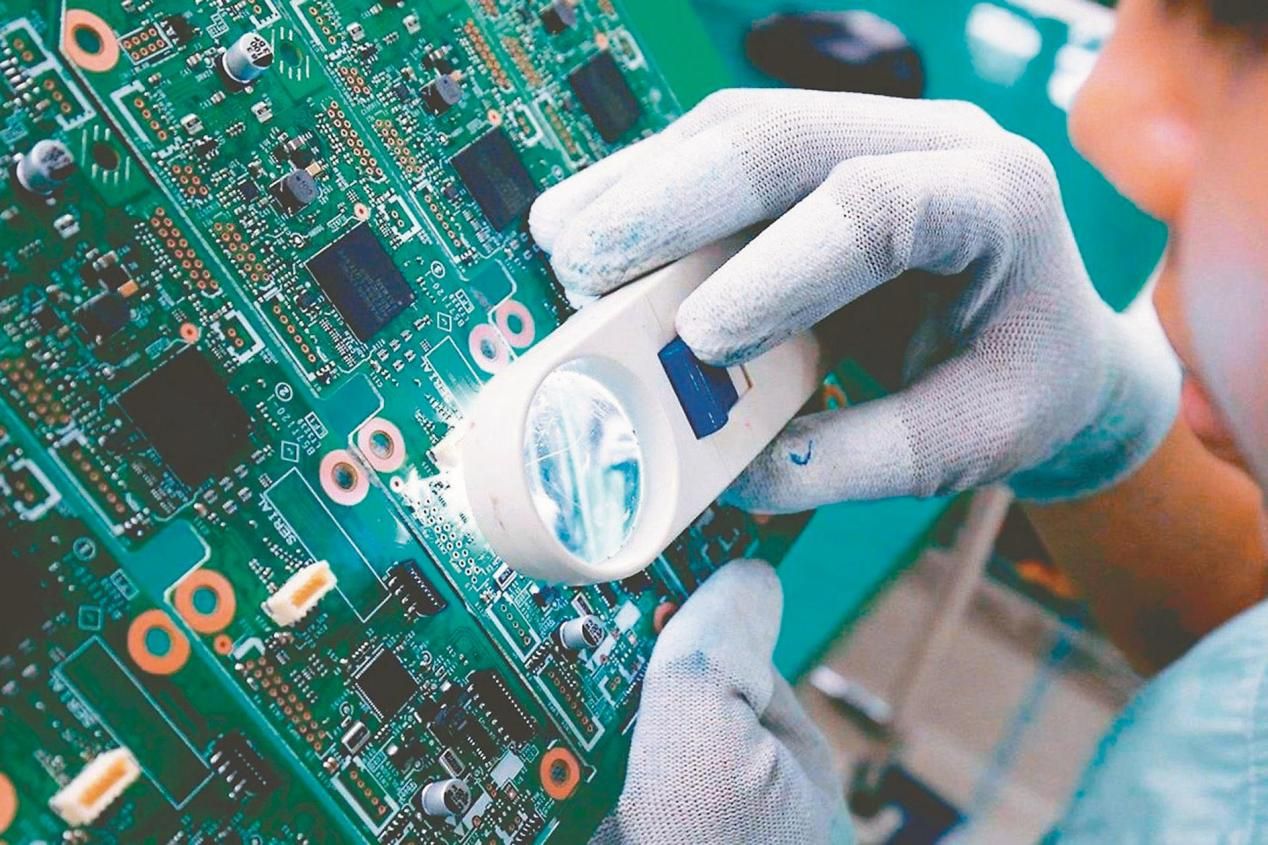

2.Electronic Waste Management:

Proper disposal of electronic waste (e-waste) generated from obsolete PCBAs remains paramount. In 2024, the industry is focused on:

Responsible Disposal Practices: Implementing efficient e-waste disposal methods, including recycling and certified disposal, to prevent hazardous materials from polluting landfills and ecosystems.

Extended Producer Responsibility (EPR): Embracing EPR policies to encourage manufacturers to take responsibility for end-of-life product management, promoting recyclability and facilitating collection and recycling programs.

Recovery of Critical Materials: Developing techniques for recovering precious metals and rare earth elements from e-waste to conserve resources and reduce the environmental impact of mining.

3.Energy Consumption Reduction:

Addressing energy consumption in PCBA manufacturing is pivotal for environmental sustainability. In 2024, the industry is focused on:

Energy-Efficient Processes: Deploying energy-efficient equipment and technologies to optimize energy usage during PCBA production, thereby reducing carbon emissions.

Renewable Energy Integration: Transitioning to renewable energy sources such as solar and wind power to power PCBA manufacturing facilities, reducing reliance on fossil fuels.

Process Optimization: Embracing lean manufacturing principles and process optimization techniques to enhance energy efficiency, minimize material waste, and improve resource utilization in PCBA production.

In conclusion, as we navigate the evolving landscape of PCBA manufacturing in 2024, it's imperative to prioritize environmental sustainability. By embracing sustainable practices across the PCBA lifecycle—from material selection to end-of-life disposal—the industry can mitigate its environmental impact and pave the way for a greener future.